DIMENSIONAL CONTROL

Dimensional control of internal shapes

Description

When it is necessary to make the impression of a specific area within a part, it is first necessary to evaluate the constraints of the part. Indeed, depending on the properties of the part, we will not use the same plastiform.

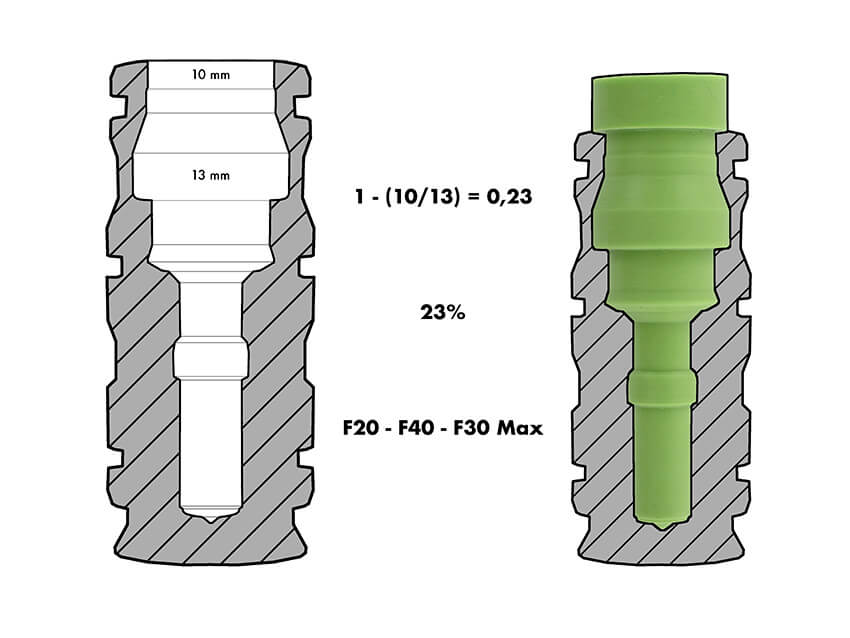

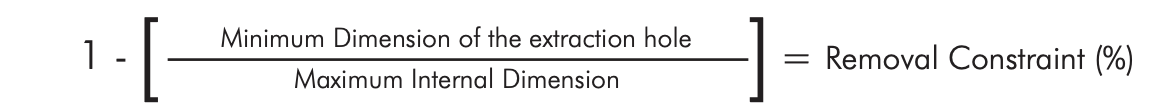

The most important constraint is the Removal Constraint, it is a simple mathematical calculation that allows to evaluate the possibility of extracting the impressions. Internal undercuts and re-entrant angles lead to a high removal constraint. The higher it is, the more difficult it will be to extract the impression, and therefore, the choice of product to use will have to be adapted.

The removal constraint (or extraction constraint) is a ratio that is calculated as follows:

Depending on this constraint, a suitable product will be chosen, thanks to the product table.

Once the product has been selected, the moulding process can begin.

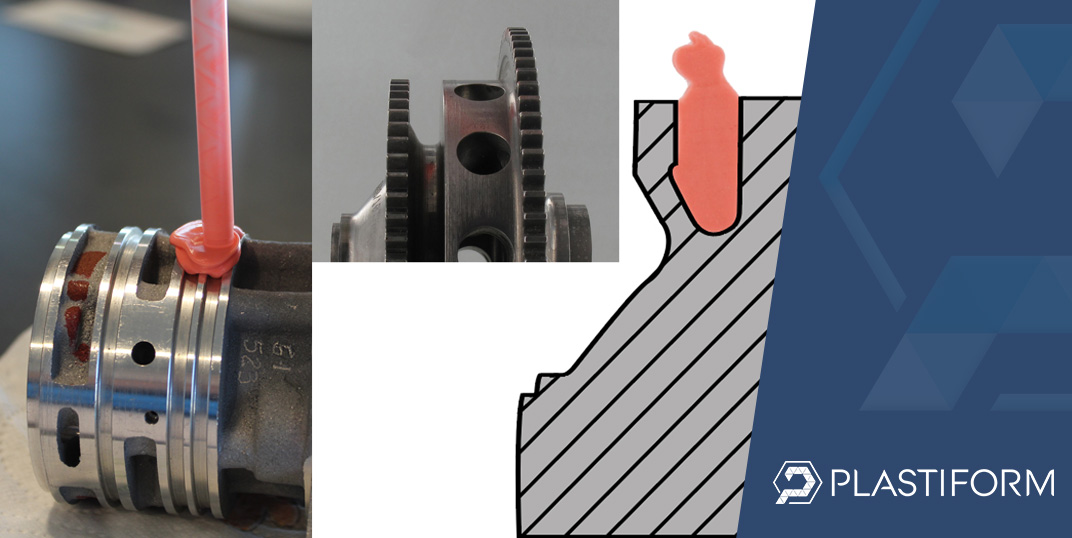

- First, it is essential to degrease your part with the degreaser validated by Plastiform: the DN1 KRISTAL.

- When you start pouring the product, be sure to use a tip so as not to create air bubbles. Mix gently while injecting the product, place and fill the demolding ring and allow the product to harden.

- The plastiform occupying all the available space, it will reproduce the dimensions of your part to the nearest micrometer.

- To extract the impression, it is necessary to pull in the axis of the extraction hole, the impression is shape memory, even if it deforms, it will always come back to the shape memorized during polymerization.

- In order to control the replica obtained, opt instead for a visual measurement system, which will allow you to obtain more accurate results.

Feel free to use the Double Blade Cutter whenever possible, it will greatly improve the ease of positioning the profile to be controlled.

Dimensional control of external shapes

Description

The case of external shapes requires additional elements to be taken into account when compared to taking an internal shape impression.

The choice of the product is made according to the area to be controlled, its difficulty of control and also according to its external environment (orientation, accessibility, etc…).

Plastiform has developed different product consistencies : pasty, fluid or malleable. Each of them can be suitable for external impression taking, although the use of pasty or malleable plastiforms is generally recommended due to their non-flowing properties.

When the surface to be inspected does not have a complex shape that can prevent demoulding (no removal constraint), it is recommended to choose a plastiform with a semi-flexible final consistency. As the latter can be sliced by the Double Blade Cutter, their control is much easier. The P35 or the M70 are the ideal products for this type of situation.

If the constraint is too high, a most flexible products should be chosen. Some of them have been specially developed for the extraction of a complex external shape, allowing the user to extract its shape while keeping the possibility of cutting its profile. These are P25 and M25.