Part holding, clamping and reinforcement before machining

Reinforcement of parts during machining

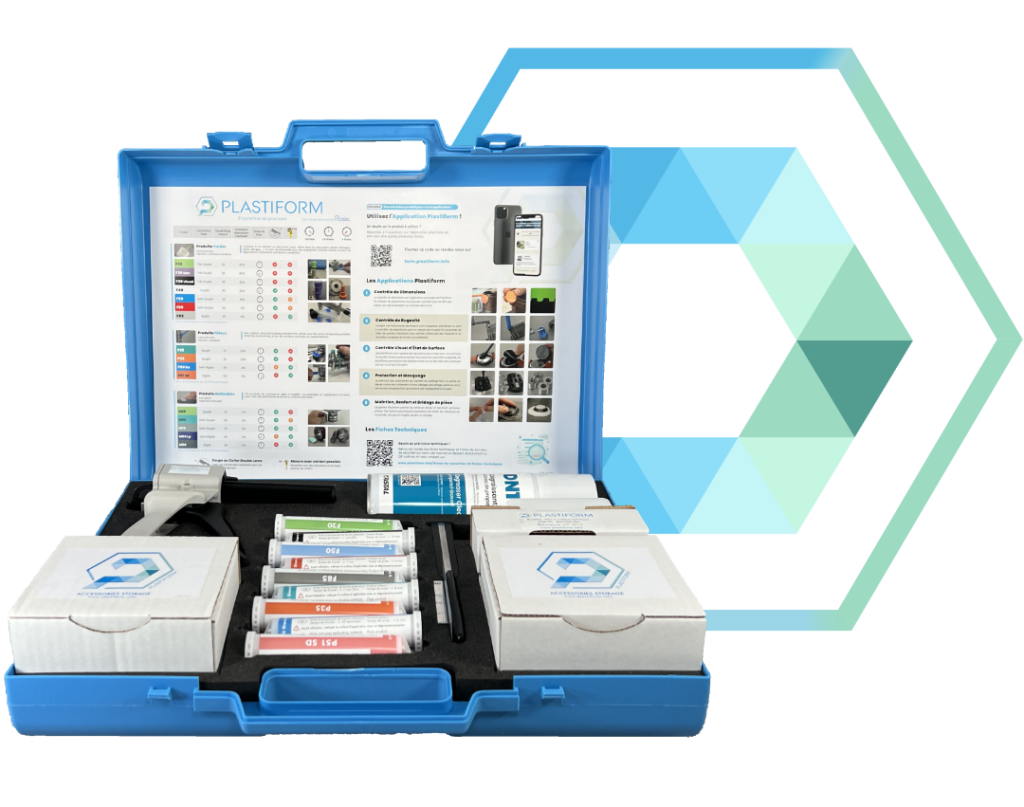

Description

During the machining steps, it is common for some thin parts to resonate or deform slightly. To limit these phenomena, it is possible to use a plastiform to reinforce them. They are easy to apply, quickly harden afterwards and are easy to extract after machining.

However, there is a different way to reinforce a fragile part than plastiforms. Re-Form is a product in the Plastiform range that is very shapeable when applied and becomes extremely rigid when cured. It is a thermoformable resin, reusable at will. When heated to 60°C or higher, it becomes transparent and malleable, then hard and extremely resistant when cooled.

In order to extract the part once the machining is complete, simply soak the Re-Form in hot water at more than 60°C to make it soft again.

You can repeat the process

whenever you need to reuse this product, even if it has been damaged

Holding and Clamping

Description

It is often necessary to hold or clamp a part during machining, that means to ensure that it does not move or vibrate. Whether the parts are small or large, plastiforms and Re-Form do this application very well.

The Re-Form, in particular, holds a part with extreme firmness and allows the tooling to come and work the parts without the risk of causing them to move.

Plastiforms and Re-Forms can perform various holding or clamping tasks, in particular:

- Protect a part when tightening,

- Create a mounting base,

- Provide additional mechanical rigidity to a part.

Since our products are all capable of handling this application, you may not know which one to choose.

If you think you need more specific advice on this application, our experts will analyze with you which product will best meet your needs.