VISUAL CONTROL OF SURFACE CONDITION

Assessment of the surface condition

Surface condition assessment

During certain production steps, it is necessary to check the condition of the surface of the machined part. Often metallic grey, the parts reflect light and make it difficult for the operator to inspect their surface finish. Sometimes, the inspection is impossible to make because it is in a space that is too small or inaccessible for the operator.

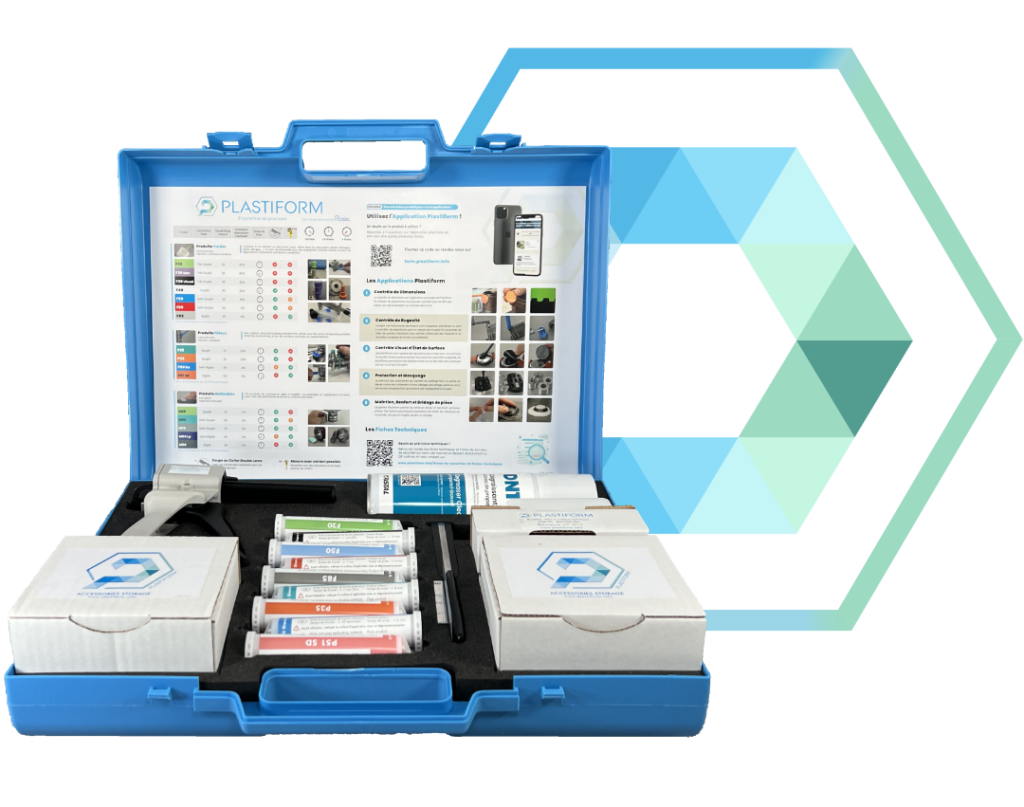

To overcome this problem, Plastiform has developed the F30 Visual. Thanks to its black colour, it copies and retransmits the surface details in a way that is easier to control, so that even the slightest defect can be quickly detected. In addition, its high fluidity allows it to slip into any corner and its elasticity allows it to be easily removable.

Methodology

Before attempting an impression, it is very important to degrease and clean the surface with the degreaser DN1.

The F30 Visual is very fluid, so be careful how you take the impression so that it does not flow anywhere. The Plastin can help you to make a formwork to facilitate the application.

When the impression is made, the product should be allowed to cure for about 10 minutes. Its exceptional precision will reproduce the surface quality of the part to the smallest detail to the nearest micrometer. Then, you will only need to use any optical vision system to analyze the results obtained.

The F30 Visual is a product that is applied using an injector and a tip, care must be taken not to create air bubbles when taking the impression. Finally, try to apply as much as possible on a flat surface. This way, you will get an image that is easy to use and the product can be easily spread over the target area.

F30 Visual

F30 Visual is an extremely fluid product, which infiltrates very easily into any cavity. Whether small (diameter up to 0.1 mm) or medium size, the product infiltrates and occupies a maximum of space, with...